I had to take apart the spindle again because one of the hall sensors disconnected...

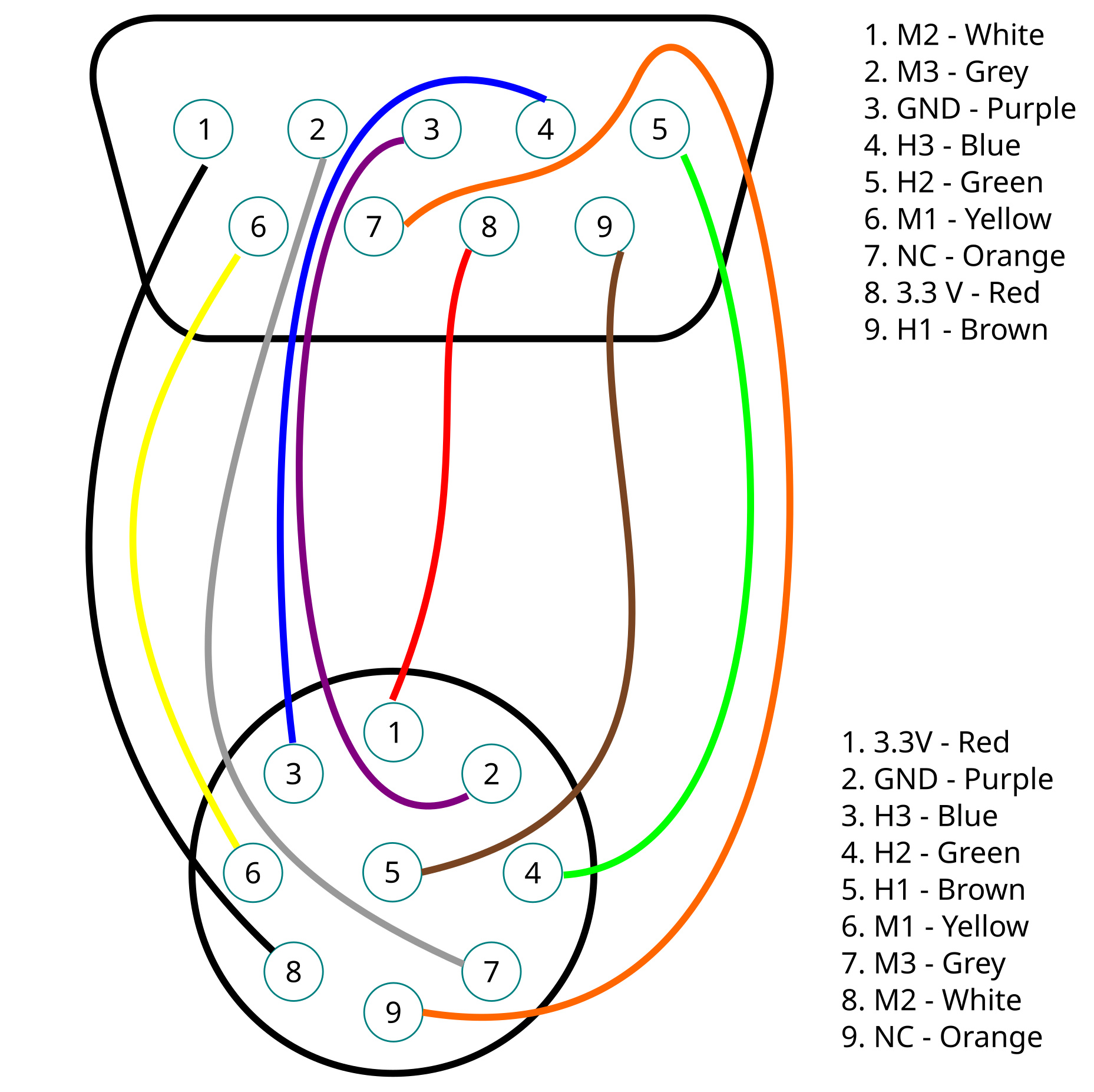

The spindle is a BLDC motor with hall sensors in a 45 degree arrangement. For reference for anyone with one of these machines here is the pinout:

To test the hall sensors:

If one does not toggle it is likely a bad connection, blown sensor, or a short. If it is shorted it may try to toggle but be a very low output voltage.

To test for shorts, check connectiviity from each pin between the pin and case of the motor or spindle housing. Only the ground pin should be connected, all others should read open.

On mine the protective plastic spacer had disintegrated so it was shorting to the housing and the solder connection came apart (hint use flux!).

Now the motor is again back in business.