A short post on my micropython PCB reflow oven...

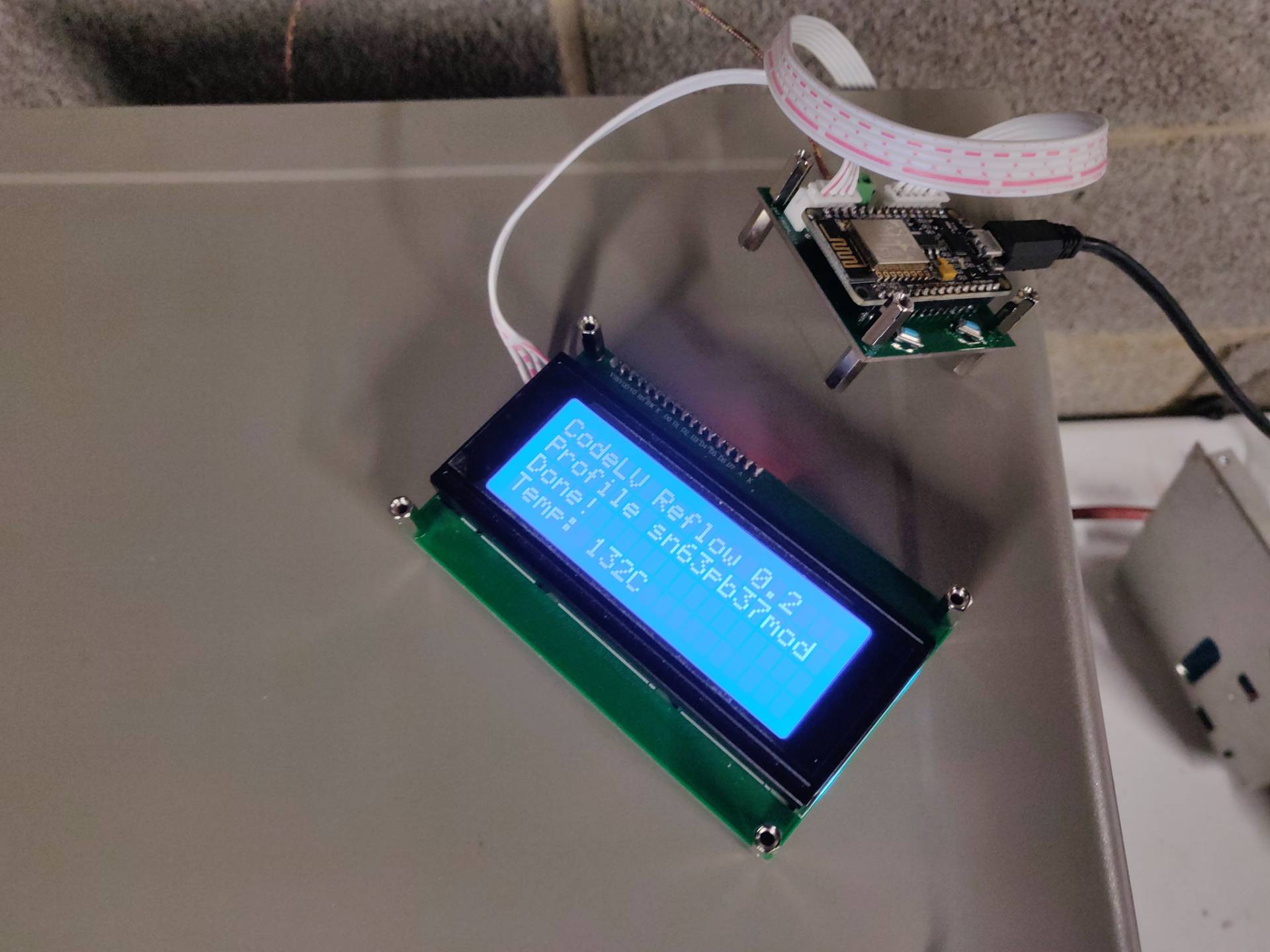

The total cost is about $100. The oven has two separate heaters and a convection fan. The software is micropython on an esp8266. You push a button and it runs the profile, nothing fancy.

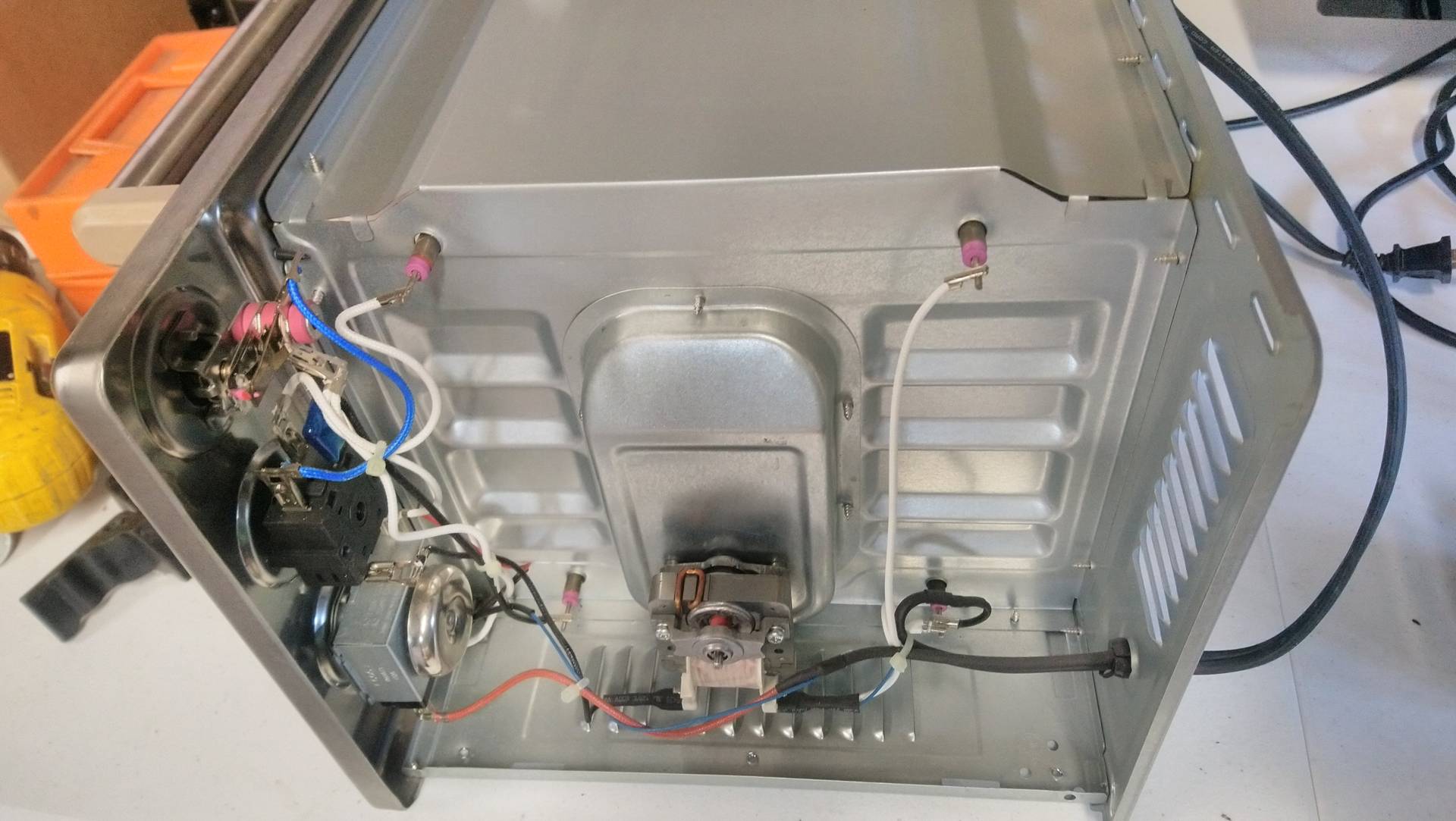

Take the cover off the over and drill a hole for the thermocouple.

Put high temp stove insulation around it (optional).

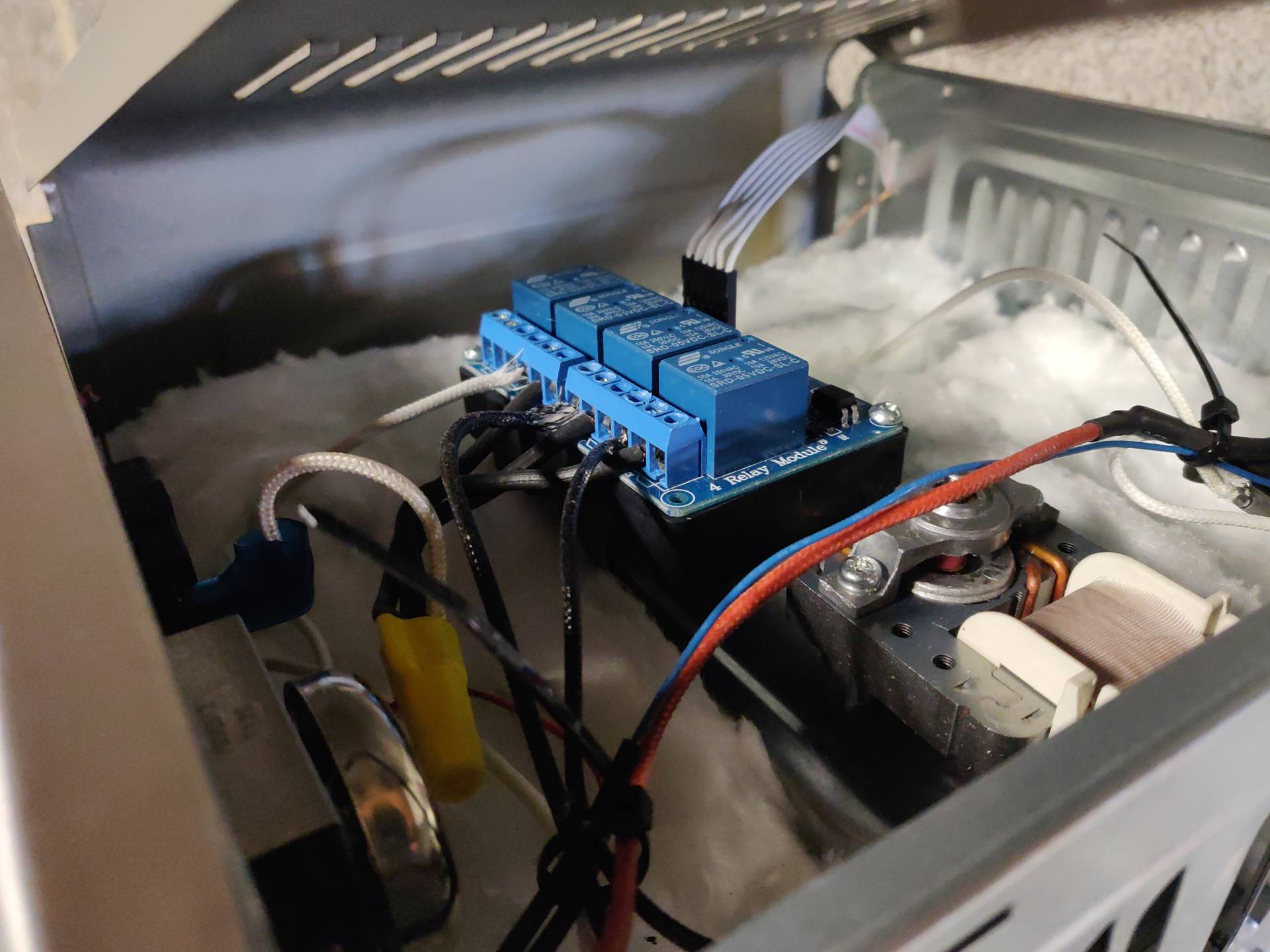

Rewire the oven so elements so the top and bottom go on separate relays, and the fan on another. The controller switches the heaters on at slightly different times to reduce surge. The 4th relay is not used but could be for something.

I happened to have a piece of plastic from a coffee maker that worked as a mount for the relay board but anything will work to keep it off the case.

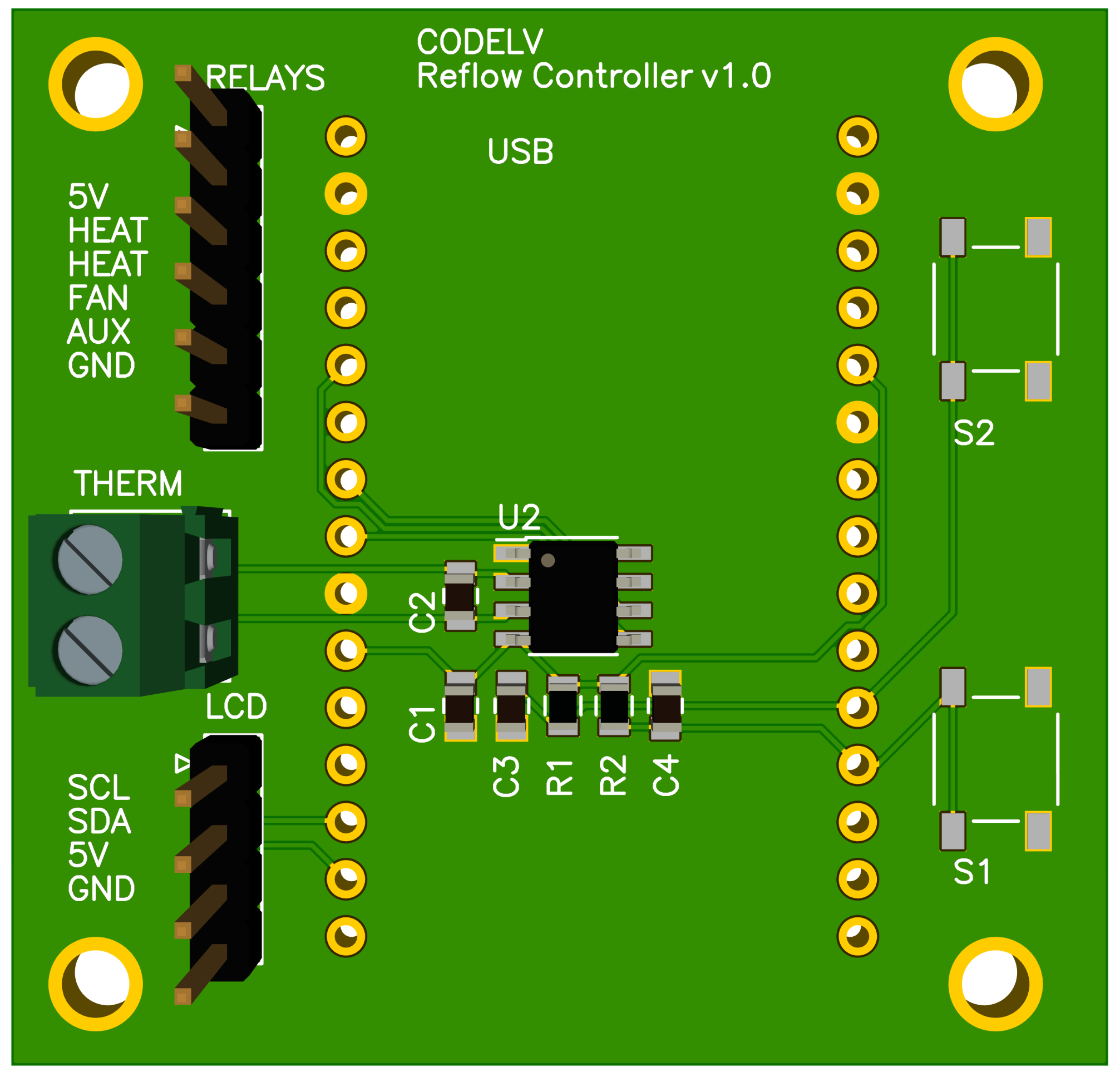

The controller is just a little breakout board made with horizon eda. It's about as simple as it gets.

Unfortunately the esp8266 is limited in it's gpio pins and the S2 button does not work (it causes a reset).

If you want the fab files to make your own send me a message.

Flash micropython for the esp8266. Then upload the following files. I use an little editor I made called micropyde. But you can use the esptool to flash the firmware and whatever to upload the files..

max31855.py the thermocuple driver. I think this is from adafruit.

import ustruct

class MAX31855:

"""

Driver for the thermocouple amplifier.

MicroPython example::

import max31855

from machine import SPI, Pin

spi = SPI(1, baudrate=1000000)

cs = Pin(15, Pin.OUT)

s = max31855.MAX31855(spi, cs)

print(s.read())

"""

def __init__(self, spi, cs):

self.spi = spi

self.cs = cs

self.data = bytearray(4)

def read(self, internal=False, raw=False):

"""

Read the measured temperature.

If ``internal`` is ``True``, return a tuple with the measured

temperature first and the internal reference temperature second.

If ``raw`` is ``True``, return the values as 14- and 12- bit integers,

otherwise convert them to Celsuius degrees and return as floating point

numbers.

"""

self.cs.off()

try:

self.spi.readinto(self.data)

finally:

self.cs.on()

# The data has this format:

# 00 --> OC fault

# 01 --> SCG fault

# 02 --> SCV fault

# 03 --> reserved

# 04 -. --> LSB

# 05 |

# 06 |

# 07 |

# > reference

# 08 |

# 09 |

# 10 |

# 11 |

# 12 |

# 13 |

# 14 | --> MSB

# 15 -' --> sign

#

# 16 --> fault

# 17 --> reserved

# 18 -. --> LSB

# 19 |

# 20 |

# 21 |

# 22 |

# 23 |

# > temp

# 24 |

# 25 |

# 26 |

# 27 |

# 28 |

# 29 |

# 30 | --> MSB

# 31 -' --> sign

if self.data[3] & 0x01:

raise RuntimeError("thermocouple not connected")

if self.data[3] & 0x02:

raise RuntimeError("short circuit to ground")

if self.data[3] & 0x04:

raise RuntimeError("short circuit to power")

if self.data[1] & 0x01:

raise RuntimeError("faulty reading")

temp, refer = ustruct.unpack('>hh', self.data)

refer >>= 4

temp >>= 2

if raw:

if internal:

return temp, refer

return temp

if internal:

return temp / 4, refer * 0.0625

return temp / 4

The lcd driver lcd20x4.py based on a github project in the comment. Slightly touched up.

# From https://github.com/dork3nergy/lcd_2004

import machine

from time import sleep_ms

class LCD:

# initializes objects and lcd

ENABLE = 0x04 #Set Entry Mode

RS = 0x01 # Register select bit

WIDTH = 20

def __init__(self, addr, scl, sda):

self.i2c = machine.I2C(scl=machine.Pin(scl), sda=machine.Pin(sda))

self.address = addr

self._backlight = 0x08 # Set Backlight ON

self.write(0x03)

self.write(0x03)

self.write(0x03)

self.write(0x02)

self.write(0x20 | 0x08 | 0x04 | 0x00) # Set Functions 2Line,5x8,4Bit Mode

self.write(0x08 | 0x04) # Turn Display On

self.write(0x01) # Clear Screen

self.write(0x04 | 0x02) # Set Entry Mode Left -> Right

sleep_ms(300)

def strobe(self, data):

self.i2c.writeto(self.address, bytes([data | LCD.ENABLE | self._backlight]))

sleep_ms(1)

self.i2c.writeto(self.address, bytes([(data & ~LCD.ENABLE | self._backlight)]))

sleep_ms(1)

def write_four_bits(self, data):

self.i2c.writeto(self.address, bytes([data | self._backlight]))

self.strobe(data)

def write(self, cmd, rs=0):

# write a command to lcd

self.write_four_bits(rs | (cmd & 0xF0))

self.write_four_bits(rs | ((cmd << 4) & 0xF0))

def set_line(self, line, col=0):

if line == 1:

self.write(0x80+col)

if line == 2:

self.write(0xC0+col)

if line == 3:

self.write(0x94+col)

if line == 4:

self.write(0xD4+col)

def display_line(self, line, data):

# Write a full line

left = 20 - len(data)

self.set_line(line, 0)

for c in data[0:20]:

self.write(ord(c), LCD.RS)

for i in range(left):

self.write(ord(' '), LCD.RS)

def display(self, data, line=0, col=0):

self.set_line(line, col)

i = 1

for c in data:

if ((i > LCD.WIDTH) & (line < 4)):

line = line + 1

self.set_line(line,0)

i = 1

if ((i > LCD.WIDTH) & (line == 4)):

break

self.write(ord(c), LCD.RS)

i = i + 1

def off(self):

self.write(0x08 | 0x00)

def on(self):

self.write(0x08 | 0x04)

def clear(self):

self.write(0x01) # Clear Screen

self.write(0x02) # Set Home

def backlight(self, on):

if on:

self._backlight = 0x08

else:

self._backlight = 0x00

self.write(0)

pid.py is a simple pid controller. For my oven it didn't make much of a difference and a simple on off would also work.

import time

class PID:

def __init__(self, p, i, d):

self.kp = p

self.ki = i

self.kd = d

# (last_value, integral, derivative)

self.state = [0.0, 0.0, 0.0]

self.last_update = None

self.last_result = None

def start(self, t, actual):

self.last_update = t

self.state = [actual, 0.0, 0.0]

self.last_result = None

def update(self, t, target, actual):

# Check for initial update

if self.last_update is None:

raise RuntimeError("Must use start first")

dt = time.ticks_diff(t, self.last_update)

if dt == 0:

return self.last_result

self.last_update = t

error = target - actual

last_error = self.state[0]

p = self.state[0] = error

i = self.state[1] = self.state[1]*0.9 + error * dt

d = self.state[2] = (error - last_error)/dt

self.last_result = (self.kp * p) + (self.ki * i) + (self.kd * d)

return self.last_result

solder profile, from github. I can't find the project anymore.

{

"title": "Lead 183",

"alloy": "Sn63/Pb37",

"melting_point": 183,

"temp_range": [30,235],

"time_range": [0,400],

"reference": "https://www.chipquik.com/datasheets/TS391AX50.pdf",

"stages": {

"preheat": [30,100],

"soak": [120,150],

"reflow": [150,183],

"cool": [240,183]

},

"profile": [

[0,23],

[90,100],

[120,140],

[180,150],

[190,160],

[220,183],

[280,230],

[300,235],

[330,230],

[350,183],

[400,23]

]

}

Note: This is an extended duration profile since my oven has a damaged heater and heats up too slowly.

The main.py file puts it all together.

import os

import json

import time

from machine import Pin, Signal, SPI

from max31855 import MAX31855

from pid import PID

from lcd20x4 import LCD

class ReflowOven:

Kp = 150

Ki = 0.1

Kd = 40

def __init__(self):

# Relay board is active low so on is off

self.heat = Signal(Pin(16, Pin.OUT), invert=True)

self.heat.off()

self.aux = Signal(Pin(2, Pin.OUT), invert=True)

self.aux.off()

self.fan = Signal(Pin(0, Pin.OUT), invert=True)

self.fan.off()

self.btn1 = Pin(10, Pin.IN, Pin.PULL_UP)

self.btn2 = Pin(9, Pin.IN, Pin.PULL_UP)

self.cs = Pin(15, Pin.OUT)

self.spi = SPI(1, baudrate=5000000, polarity=0, phase=0)

self.sensor = MAX31855(self.spi, self.cs)

self.lcd = LCD(0x27, 5, 4)

self.display_line(1, "CodeLV Reflow 0.2")

def display_line(self, number, message):

self.lcd.display_line(number, message)

def find_profiles(self):

return [f for f in os.listdir('.') if f.endswith('.json')]

def load_profile(self, profile):

self.display_line(2, "Profile %s" % profile[0:-5])

f = open(profile)

try:

return json.load(f)

finally:

f.close()

def get_target(self, profile, t):

last = None

for p in profile['profile']:

# Find the points along the time axis

if t < p[0]:

if last is None:

return p[1] # Start point (should never occur)

# Calculate target using linear interpolation

slope = (p[1] - last[1]) / (p[0] - last[0])

dt = t - last[0]

return slope * dt + last[1]

last = p

return 0 # Done

def heatup(self):

print("Heatup")

self.heat.on()

time.sleep(0.1) # Reduce surge

self.aux.on()

def cooldown(self):

print("Cooldown")

self.heat.off()

self.aux.off()

def read(self, retries=3):

for i in range(retries):

try:

return self.sensor.read()

except RuntimeError as e:

time.sleep(0.1)

print(e)

raise ValueError("Could not read sensor")

def run(self, profile):

self.display_line(3, "Status: Running")

print("Running %s" % profile["title"])

# PID values

controller = PID(ReflowOven.Kp, ReflowOven.Ki, ReflowOven.Kd)

# Control loop

start_time = time.time()

end_time = profile['time_range'][1]

dt = 0

controller.start(dt, self.read())

btn1 = self.btn1

self.fan.on()

try:

state = False

time.sleep(0.1)

while dt < end_time:

time.sleep(1)

dt = time.ticks_diff(time.time(), start_time)

target = self.get_target(profile, dt)

temp = self.read()

r = controller.update(dt, target, temp)

print("Time: %s Target: %s C, Temp: %s C" % (

dt, target, temp))

print("Result: %s, State: %s" % (r, controller.state))

left = int(end_time - dt)

self.display_line(3, "Time %ss Left %ss" % (dt, left))

self.display_line(4, "Temp %sC Set: %sC" % (int(temp), int(target)))

if not btn1.value():

self.display_line(3, "Cancelled!")

time.sleep(1) # Don't restart

return

# Update heat mode

new_state = r > 0

if state != new_state:

state = new_state

if state:

self.heatup()

else:

self.cooldown()

self.display_line(3, "Done!")

print("Done!")

except Exception as e:

self.display_line(3, "Stopped!")

raise e

finally:

self.cooldown()

self.fan.off()

def monitor(self):

btn1 = self.btn1

temp = 0

while True:

try:

temp = self.read()

except KeyboardInterrupt:

break

except Exception:

pass

self.display_line(4, "Temp: %sC" % (int(temp),))

if not btn1.value():

return

oven = ReflowOven()

profiles = oven.find_profiles()

print("Profile files are: %s" % profiles)

print("Load one and run to start")

profile = oven.load_profile('sn63pb37mod.json')

oven.display_line(3, "Ready.")

while True:

oven.monitor()

if not oven.btn1.value():

time.sleep(1) # Allow time for release

oven.run(profile)

Just upload and reset. Then push the first button to start. And again to cancel if needed.

It seems to work fine. So far I've made 50 or so boards for random stuff but never had any problems with not reflowing. The only problems I've had was bridging on fine pitch parts with my home-made stencils.

The lower elements on mine happend to be damanged but it still works fine. I usually do a warm up run if it's cold in the garage. I also open the door when it gets to the cooldown stage because the insulation retains the heat too long.

Anyways, hope you found something helpful here. Take care!